So we are into the final countdown now for the completion of the house – hopefully by week 35 the builder will be able to turn over the house to us – once we make the final payment & defect corrections are complete.

These last few weeks are both exciting & challenging. When you can see the finish line, there is urgency to get there. Any days without work on the house is frustrating – but our tried patience must prevail – we will get into the completed house eventually.

House Build Week 32

YouTube Channel – this weeks video of building activity offers a visual summary of the progress achieved. (Check it out – click link) – Week 32 House Build

This weeks saw a number of things completed.

Door Frames – these have been installed in all the internal rooms (bedrooms, utility & bathrooms) of the house along with the two external doors (one from the side porch & one to the carport store room). We are using ‘Yes Moulding’ doors & frames that come as a multi-piece set. The door installer has not used these before but quickly worked out the process to install and finish the frames. Firstly he puts together and installs the 3 sided frame. He then puts in place a sub-frame and finishes off with the frame moulding. We like the color chosen as it will match and compliment the flooring.

House Front Door – I was excited about this install. A bit of a feature aluminum door that was to stand out. It is a 165 cm opening that holds 2 doors that (as supplied) work off a double swing hinge system – the doors open both inwards and outwards. It has a teak wood appearance and does look nice. However, given the nature and structure of this swing door system it is not a one way framed door so there is not proper sealing around the doors. Something we need to have further discussions with our builder about. We had asked for an inward opening door – expecting it to be one way only with a normal frame and seal. I expect this door will now need to be replaced & it looks like the builder agrees – at his expense.

Screens for doors and windows were installed this week. The window team arrives with the aluminum frames all built but had to install the fiberglass screen material into the frames. They set up their workshop on the back porch to complete the sliding door and window screens. All our windows will have screens. There are 3 hinges on each screen, along with 3 hold magnets to keep it closed.

Porch stairs stone – were completed by the tiler to match the black stone on the adjacent house facade. It only took a day to complete but finishes off the steps completely and compliments the overall look of the house facade. The steps and porches were then grouted to complete the finish.

SPC flooring preparation was carried out this week. A large team arrived to prepare the floor with a 3 phase treatment system. A previous floor leveling job, while generally adequate, had some flaws & a few areas where the concrete has come away from the slab. This new treatment system will solve that problem and bind the concrete together to make a very smooth surface to install the SPC flooring. They first put a wetting/penetration solution on the whole house floor. That was followed by an application of a crystal bond primer. It was poured out onto the floor and then with a roller it was spread evenly around (much like painting the floor). It prepares the floor to accept the final mortar levelling solution. They added a mortar plus mixture to normal mortar and water to make a very wet slurry mixture. This mixture was then poured out over the floors as a thing layer (@3 mm) to self level. It was then left to dry. The next day they returned to inspect the preparation & delivered 61 boxes of Cotto LT SPC floor tile – to be installed next week.

Kitchen Cabinets were delivered and installed. The cabinets were made by Kitzcho in an Olive Green color. Homepro from Mukdahan delivered these pre-made upper and lower cabinets. We separately payed the tiler to install these cabinets – he had done this work previously and it was less expensive than having Kitzcho or Homepro do the work. All the installation went according to the plan, up until the last two cabinets.

It turned out that the cabinets stuck out beyond the planned tiled area by about 6 cm. After some head scratching & calls to the Kitzcho designer at Homepro it turned out that the original plan had a 60 cm cabinet, put the designer had made a change to the design (without informing us) and replaced that cabinet with an 80 cm unit. Our kitchen design and tiled area was based on the original plan, not the unknown revision. It all turned out nicely, as Kitzcho sent out a technician a few days later to make adjustments to an end corner cabinet that could be cut down in size to ensure the cabinets aligned correctly to the finished wall. Happy with the results.

Site tidy up also began this week. Along with taking down the site storage shed & organising site material into piles the worker also spread the dirt around the house to cover up the water supply pipes and used a vibrating compactor to level out the soil adjacent to the sidewalks. The site is looking a bit more finished.

House Build Week 33

YouTube Channel – this weeks video of building activity offers a visual summary of the progress achieved. (Check it out – click link) – Week 33 House Build

As the picture shows – the plan is for only 2 more weeks until completion. There is a busy schedule to get things completed in time. The builder is behind in his schedule of works, but still thinks he can meet the agreed completion date. Ace has had a heart to heart meaningful conversation with him regarding what the contract indicates for not completing on time? This weeks activity saw the following completed:

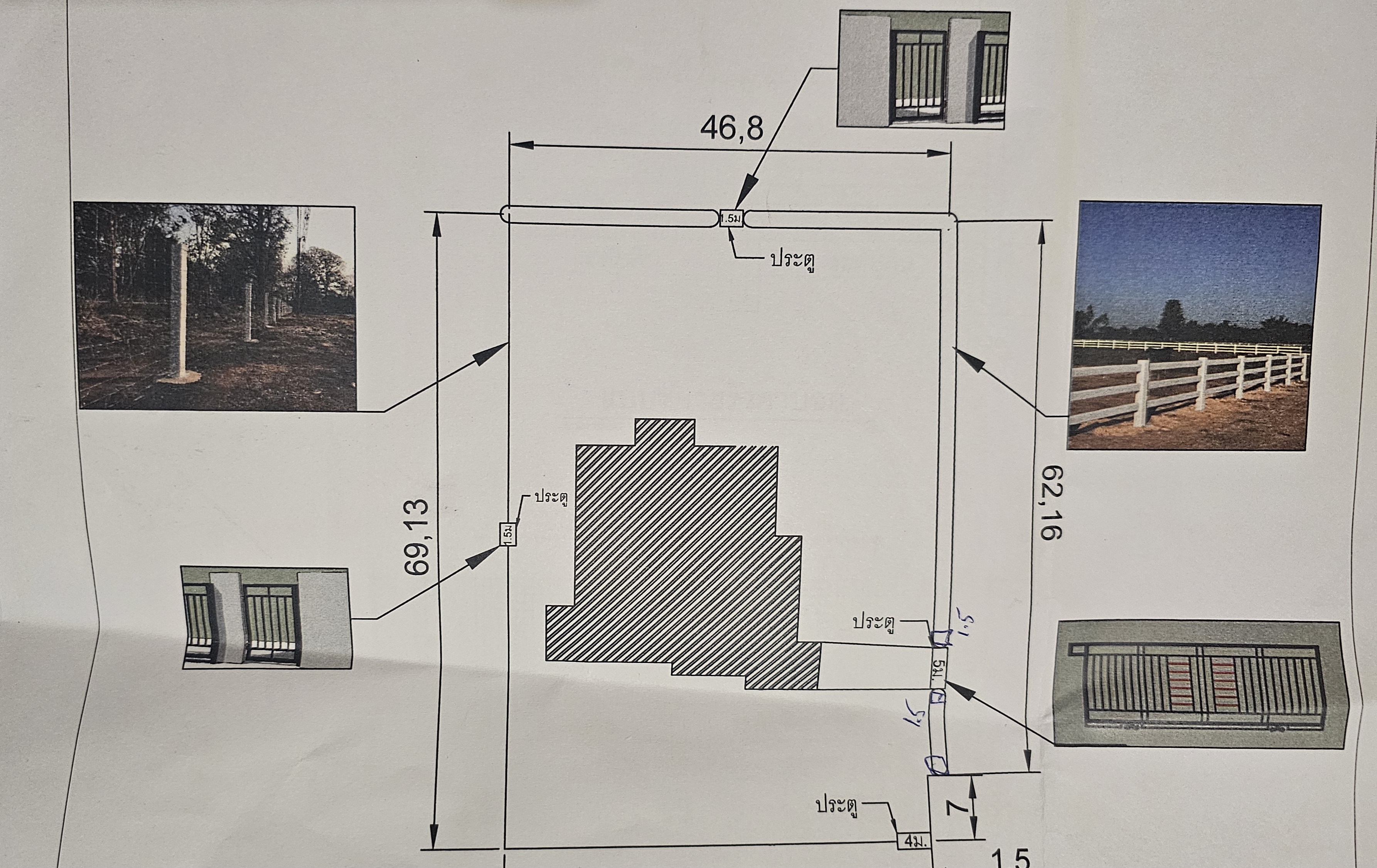

Property fencing plans this week began to take shape. We had signed a contract with a fencing contractor to install fencing all around a portion of our property. 2 sides of the property with what is referred to as a concrete “cowboy” fence with s mesh covering. And 2 other sides with a mesh fence with concrete posts. We like the look of the cowboy fence as it suits the country cottage style of the house and is adjacent to the public roads. The other two sides separate the back of our property and Ace’s mothers adjacent property. The cowboy fence supplies were delivered and installation is planned for next week.

Porch stair handrails and gates were installed this week & that completes the outside porches. The contractor had prefabricated the handrails and gates in his shop and brought them to site for installation. This involved 2 days of onsite work to weld the handrails to the installed railings and mount the sliding gates along with finish off painting of the metal and tidy up work. The results look nice and the sliding gates operate very smoothly.

Electrical installation also began this week. The electrician & his helpers were onsite to complete works to have hanging lights, switches, plugs and fans installed and working. They also cut out the ceiling holes for the round LED lights. He hooked up the house to temporary power to test the lights and switches – it looked really good in the evening with the some of the lights on. Next week all the electricity works will be finished up including installing recessed ceiling lights & breaker boxes, ready to be connected to main meter & power from PEA.

SPC flooring & skirt board installation also took place this week. Last week the floor was levelled so prior laying the floor they started by scrapping the levelling concrete to take off any rough edges & ensure a smooth surface. Once the floor was cleaned plastic sheeting was fitted on the floors as a moisture barrier & this was followed by the laying of the SPC pieces. It is a click lock system with the pieces locking into each other and a rubber mallet is used to ensure they lock securely together. It is not glued to the floor but is a floating system. They used a laying pattern of 3 row staggering & repeat so that the floor has a difference in the length of the flooring piece – something like a really old fashioned wood floor might look.

The Cotto SPC has a really nice wood look finish with a wood grain feeling when you run your hand over it. We used the LANZE-LM SNE06 color model that is 23 cm x 152 cm & is 6 mm thick with a 0.5 mm wear layer. It has a 4 layer construction – a wear layer, a print film, a middle rigid core board with click lock technology and a bottom layer of foam for smoothness. The following day the team returned to install the skirt board that helps lock the floor in place and provides the finished look. The skirt board was also from Cotto and similar in color pallet. We are happy with the finished look and feel when walking on it.

Door hanging also took place this week. With frames previously installed it was time to get the doors mounted into the frames. The team spent about 3 days this week to complete the installation of 2 door frames & hanging of 9 doors. The doors are fairly substantial and require 4 hinges each. We have chosen a blackened copper color for the handles, hinges and door holders.

More site clean up took place this week with the contractor removing all the building materials & form work from the site. Much of the construction items were moved to a new site he is going to build. This has made a big difference to the look of the place. There is still some odd bits and pieces yet to be cleaned up along with the car port that has lots of left over tile and cement/mortar bags laying around.

House Video tour – on Sunday 1 December 2024 & how the inside is looking so far. We are ready for the last two weeks of works to complete house – if the builder gets his act together and we are looking forward to the end.

Next week – it is anticipated we will see the finishing of the electrics, painting, and hopefully the plumbing, sanitary & the water tank/supply. The fencing contractor will also be progressing the installation.

I am hopeful that the next report will be the last in the building series, however, there will a few on landscaping and follow up issues to cover, not mention the move to the new house. Cheers