Where have the last two weeks of May gone, as it is now the end of the first week of June. I have also been a bit negligent in posting the previous 2 week update. I have been unwell on many fronts & doing things on the computer has not been an option. Things are improving, so that is a good sign.

Progress was made over the last two weeks of May in completing the main (plinth) beam that supports the house floor. It is now starting to look like a house build. The build team took a break during week 7 to allow for the curing of the cement after pouring the main beam. Only 25 more weeks to go (!?!) of the planned 32 week build – if all goes without drama & to the builders schedule. The builder has indicated he is 2 weeks behind schedule at this point.

Build Week 6 (20 – 26 May 24)

YouTube video of this weeks activity is a good summary (click) – Week 6 Thai House Build

The work during week six involved completing the construction of the rebar beams and placing of the formwork (shuttering) around the rebar to form the main (plinth) beam. If you recall, at the end of week 5 they had just commenced the building of the plinth beam rebar & supports & installing the bottom wooden (doll) supports.

The rebar that is used is 12 mm and is formed into beams by hand. The team have grinders, saws & bending frames & tools to shape the rebar in position. There are two top and two bottom rebars; there is then a rebar loop every 5 cm along the beam. there is also other 12 mm rebar pieces that support the beam at certain intervals & also connected to the upright house columns. They are tied to together with wire that is twisted to secure them.

The rebar & formwork needed to replicate the blueprint design, that looks like this:

Remember all this rebar will be incased in concrete. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure.

You can see from these pictures (below) how the upright columns are tied/connected to the main (plinth) beam & how the rebar looks inside the formwork – ready for concrete.

The week was a challenge as it had many days of delay due to rain – it was wet, wet, wet. It made everything on site too muddy for the construction team to work. Originally they had expected to complete the form work and pour concrete but due to 3 days of rain delays the concrete pour was deferred to week 7. It took all week to complete the rebar frame and formwork. On the positive side the rain was excellent to compact the landfill we had spread out over the property.

By the end of this week all the form work was completed and ready for the concrete pour.

Build Week 7 (27/31 May)

The YouTube video of this weeks activity is a good summary (click) – Week 7 Thai House Build

This was the concrete pour week for the big plinth beam. On Monday there were 3 trucks (of 5 cue each) for a total of 15 cue (cubic meters) of SPC concrete that were delivered to site over the day. Of course you couldn’t have things run smooth.

The builder had booked 3 trucks from CPAC on Monday but when he called to confirm in the morning he was told they overbooked & couldn’t deliver. Thankfully he was able to find another SPC cement plant that could deliver the requirements on the day.

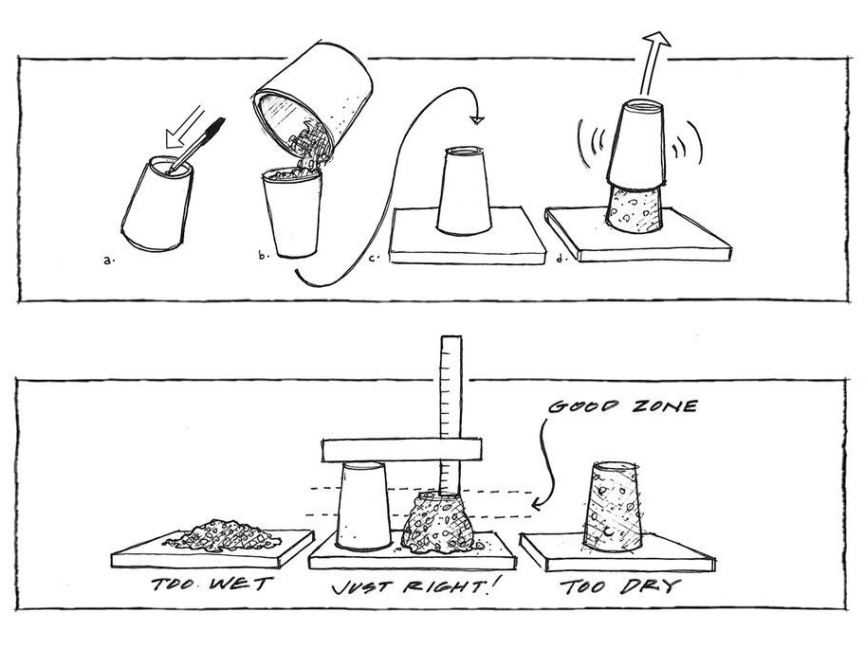

Our builder again did a slump test on the delivered concrete mixture, which was a 250 KSC strength, and apparently quicker drying. The concrete slump test measures the consistency of a concrete batch to see how easily the concrete will flow. The test not only observes consistency between batches, but it also identifies defects in a mix, giving the operator a chance to amend the mix before it is poured on site.

I observed the slump test outcome & was told that it was “just right” (within tolerance), so the concrete pour continued all day with 3 truck load. The building team worked in a group of about 12 people. The truck would pour concrete into a large black plastic tub and then hand buckets were used to pour concrete from the tub, by hand, into the formwork. A very manual labor intensive process.

As the formwork was filled up they build team would use a vibrating machine to work the concrete to ensure that it spread and settled completely throughout the forms. This was done to avoid any holes or airgaps in the beam.

By the end of the day all the concrete was poured into the forms to complete the beam. It was along and very hard labor day. After about 24 hours the side formwork was removed as the concrete had cured sufficiently. The bottom formwork for the beam was not removed & was to be left for a further week or more to cure. It looked a very good job when the formwork was removed with no gaps visible. The site foreman seemed pleased with the results.

Most of the team departed the build site for the rest of the week, with only one staying behind to water the beam a few times a day to ensure curing of the concrete was done slowly. As it turned out by Wednesday the heavens provided all the water needed to ensure the beam was kept moist for the rest of the week. After the initial 4 hours of curing time water falling on the beam is not a problem for its cure & strength.

The rain has made the building site somewhat muddy and the cement and delivery trucks have helped, along with the rain, to compact down the landfill. There will be the need for a final land shaping/grading once the construction is done.

Summary & Week 8 – So the build is now starting to take shape & you can see the structural design outline for rooms & floor space. The team will be removing the beam bottom support, installing plumbing pipes that go through or under the floor and prepare the balcony floors for concrete to be poured. The main house floor will follow. It’s all happening again.

Landscaping Ideas & Considerations

While the completed build is months away, we have been thinking about the landscaping of the property. Lots of time for planning left & it will likely be done in stages. We have located a very good garden center/nursery called Maejo Garden between our town & Nakhon Phanom.

Recently we had a meeting with the owner, who it turns out went to Maejo University in Chiang Mai doing agriculture. He provides landscaping services & has done many of the Hotels around Nakhon Phanom. So we have started a dialogue with him about helping us design our landscape plan. He has teams to deliver & plant trees, gardens & all manner of shrubbery. I am sure it will be fun to work with him on a plan to greenify our RAce Country Cottage.

Looking forward to reporting on weeks 8 & 9 of the build. Cheers